Doosan DX300LC Excavator Slipper Seal Straightening Jig Assembly

This instruction show you guide on how to assemble slipper seal straightening Jig Doosan DX300LC excavator.

Procedures:

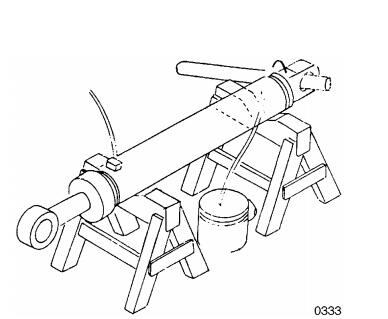

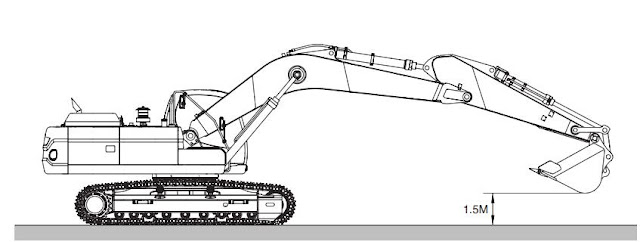

1. Following removal of cylinder from excavator attachment,support cylinder on some type of sturdy work platform and drain all oil. Rotate cylinder so that piping ports are on top,to allow trapped air to vent.Doosan DMS-5 Diagnostic Software

2. Position piston rod so that it is extended approximately one half meter (20").

3. Remove bolts (7) on the end of cylinder.

NOTE: Wrap a cloth or other protective material around piston rod, to avoid possibility of accidentally scratching or scoring rod surface while fasteners are being loosened and removed.

Component parts (numbered in parentheses) are keyed to Figure 4.

4. Tap two bolts into cover of cylinder head, 180° apart.

Tighten them in a staggered, even sequence, to back off piston rod end cover from edge of cylinder wall. Look for adequate clearance between cover and end of cylinder

wall before using a plastic or other soft-faced hammer for final disassembly.

5. Begin withdrawing piston rod assembly, away from cylinder. Attach a lifting support when final 1/3 of rod is still inside barrel of cylinder. Prepare support blocks for piston

rod before it has been completely withdrawn.

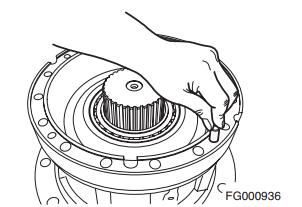

6. Lower piston rod to support blocks and detach wear ring (outer surface) (18) from end of rod.

7. Immobilize piston rod by inserting a wooden or other nonscoring, nonmetallic support through end of rod.Doosan Excavator EPC

8. Remove set screw using socket wrench.

9. Fabricate or purchase a piston nut removal wrench.

(Dimensions are called off at beginning of this procedure.

This tool may also be ordered through your local DOOSAN

Parts distributor). Remove nut from end of piston.

10. Use second piston tool described at beginning of this procedure to separate piston. Detach cushion ring (15),taking care not to damage cushion ring.

11. Use a plastic hammer to evenly pull off rod cover (9) from end of piston rod. Be careful not to damage rod bushing (6) and dust wiper, U-packing and other seals.

12. Use a dull, rounded tip tool to pry off O-ring (11) and backup ring (12).

13. Find a screwdriver with an appropriate width tip to facilitate removal of slipper seal (19), wear ring (18) and slide ring

(17) from piston (16).Doosan Excavator Workshop Manual

14. Remove O-ring (20) and backup ring (21) from cylinder head.

15. During disassembly of cylinder head, be careful not to damage buffer seal (5) and U-packing (4).

16. Disassemble retaining ring (3) and dust wiper (2). Separate retaining ring (8) and rod bushing (6).

17. Force out pin bushing (1) from body of cylinder.

Comments

Post a Comment