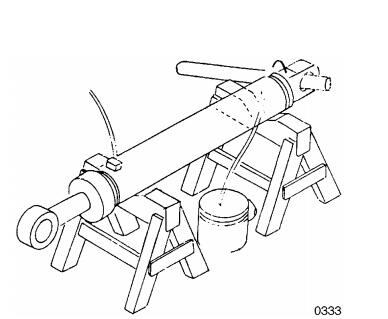

Doosan DX300LC Excavator Slipper Seal Straightening Jig Assembly

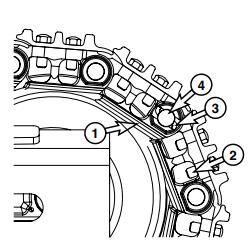

This instruction show you guide on how to assemble slipper seal straightening Jig Doosan DX300LC excavator. Procedures: 1. Following removal of cylinder from excavator attachment,support cylinder on some type of sturdy work platform and drain all oil. Rotate cylinder so that piping ports are on top,to allow trapped air to vent. Doosan DMS-5 Diagnostic Software 2. Position piston rod so that it is extended approximately one half meter (20"). 3. Remove bolts (7) on the end of cylinder. NOTE: Wrap a cloth or other protective material around piston rod, to avoid possibility of accidentally scratching or scoring rod surface while fasteners are being loosened and removed.