How to Remove and Install Counterweight for Doosan DX300L

Here is a step-by-step guide on how to remove and install counterweight for Doosan DX300L excavator.

Related Contents:

Doosan Data Monitoring System DMS-5 DMS-3 Free Download

2017 Daios Doosan GPES Part Catalog Download & Installation Service

2020 Doosan Excavator Workshop Service Repair Manual PDF Download

REMOVAL

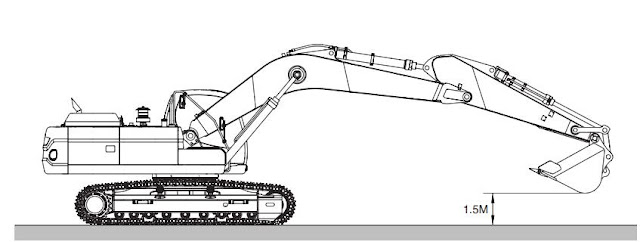

1. Park on firm and level ground.

2. Lower front attachment (bucket) to the ground.

3. Shut down engine.

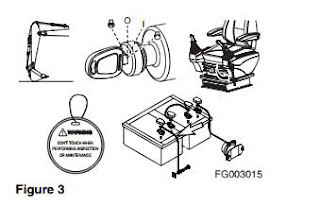

4. Set safety lever on "RELEASED" position.

5. Turn starter switch to "I" (ON) position.

7. Set safety lever on "LOCK" position.

8. Turn key to "O" (OFF) position and remove from starter switch.

9. Hang maintenance warning tag on controls.

10. Disconnect the battery cable from the negative (-) battery terminal.

11. Remove engine compartment cover.

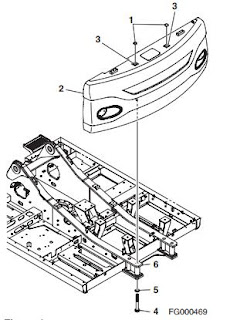

12. Remove two caps (1, Figure 4) from counterweight (2).

13. Install two lifting eyes in lifting holes (3, Figure 4).

14. Using a suitable lifting device capable of handling a heavy load, partially support counterweight (2, Figure 4) before loosening four bolts (4). Stop lifting with assist crane as soon as lifting slings are taut.

15. Remove four bolts (4, Figure 4) and washers (5) from counterweight (2).

NOTE: Heat bolts if necessary, to free them.

16. When bolts (4, Figure 4) and washers (5) have been removed, lift counterweight (2) a very short distance above support frame (6) and stop. Check slings and make sure counterweight is being supported evenly.

INSTALLATION

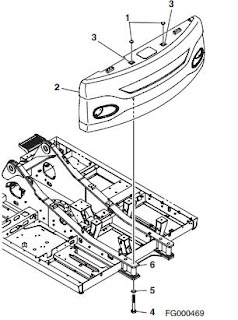

1. Using suitable lifting device capable of handling a heavy load, raise counterweight (2, Figure 5) into position just above support frame (6) leaving counterweight suspended.Verify that counterweight is level and even.

NOTE: Leave counterweight (2, Figure 5) suspended 3 mm (0.125") above support frame (6) until all four mounting bolts (4) are started in counterweight mounting holes.

2. Slide washers (5, Figure 5) onto bolts (4). Apply Loctite #242 to mounting bolt threads.

3. Install four bolts (4, Figure 5) with washers (5) into counterweight until washers contact support frame. Fully lower counterweight onto support frame and finish tightening bolts.NOTE: Torque bolts (4, Figure 5) to values shown in following table

4. Remove lifting device and lifting eyes from counterweight lifting holes (3, Figure 5).

5. Install two caps (1, Figure 5) in lifting holes (3).

6. Install engine compartment cover.https://www.car-auto-repair.com

7. Connect negative (-) battery cable to battery.

Comments

Post a Comment